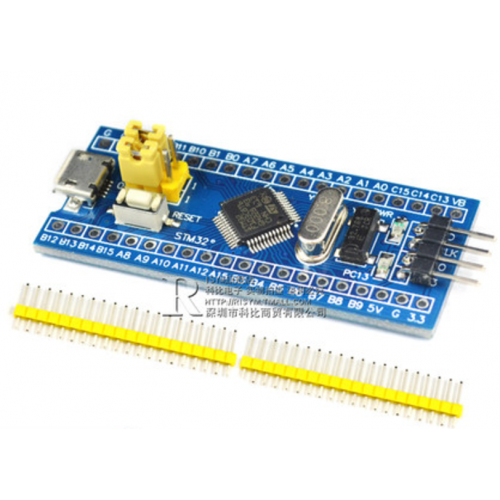

2. Buat program untuk mikrokontroler STM32F103C8 di software STM32 CubeIDE.

3. Compile program dalam format hex, lalu upload ke dalam mikrokontroler.

4. Setelah program selesai di upload, jalankan simulasi rangkaian pada proteus.

5. Selesai.

Pada percobaan ini menggunakan beberapa kompponen yaitu LDR sensor untuk membaca intensitas cahaya, resistor, STM32, buzzer dan motor DC. Rangkaian ini berfungsi untuk mengontrol kecepatan motor DC dan buzzer berdasarkan intensitas cahaya yang dideteksi oleh sensor LDR, yang pada simulasi ini diwakili oleh potensiometer. LDR menghasilkan nilai tegangan analog yang dibaca oleh mikrokontroler sebagai masukan untuk menentukan kondisi kerja motor dan buzzer. Ketika nilai ADC di bawah threshold 1600, motor DC berputar dengan duty cycle sebesar 15%, dan buzzer berbunyi dengan frekuensi tinggi. Sebaliknya, jika nilai baca ADC melebihi threshold 3100, motor DC akan berputar lebih cepat dengan duty cycle sebesar 85%, dan buzzer akan mati. Kemudian push button disini berfungsi untuk mematikan buzzer secara paksa ketika buzzer berbunyi.

#include "main.h"

ADC_HandleTypeDef hadc1;

TIM_HandleTypeDef htim1;

TIM_HandleTypeDef htim2;

void SystemClock_Config(void);

static void MX_GPIO_Init(void);

static void MX_ADC1_Init(void);

static void MX_TIM1_Init(void);

static void MX_TIM2_Init(void);

int main(void)

{

HAL_Init();

SystemClock_Config();

MX_GPIO_Init();

MX_ADC1_Init();

MX_TIM1_Init();

MX_TIM2_Init();

HAL_TIM_PWM_Start(&htim1, TIM_CHANNEL_1); // Motor PWM

HAL_TIM_PWM_Start(&htim2, TIM_CHANNEL_3); // Buzzer PWM

HAL_ADC_Start(&hadc1);

uint8_t buzzer_enabled = 1;

// Threshold

const uint16_t THRESH_LOW = 1600;

const uint16_t THRESH_MID = 3100;

while (1)

{

HAL_ADC_Start(&hadc1);

HAL_ADC_PollForConversion(&hadc1, 10);

uint32_t adc_val = HAL_ADC_GetValue(&hadc1);

// --- Motor Control ---

if (adc_val < THRESH_LOW)

{

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, 9830); // Lambat

}

else if (adc_val > THRESH_MID)

{

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, 55704); // Sedang

}

else

{

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, 0); // Cepat

}

// --- Buzzer Logic ---

if (adc_val < THRESH_LOW && buzzer_enabled)

{

// Set buzzer ke frekuensi tinggi

uint32_t period = 21000;

__HAL_TIM_SET_AUTORELOAD(&htim2, period);

__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_3, period / 2); // 50% duty cycle

}

else

{

__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_3, 0); // Matikan buzzer

}

// --- Button Logic (PB0 ditekan = nonaktifkan buzzer) ---

if (HAL_GPIO_ReadPin(GPIOB, GPIO_PIN_0) == GPIO_PIN_SET)

{

buzzer_enabled = 0;

__HAL_TIM_SET_COMPARE(&htim2, TIM_CHANNEL_3, 0); // Paksa matikan buzzer

}

HAL_Delay(10);

}

}

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

RCC_PeriphCLKInitTypeDef PeriphClkInit = {0};

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSI;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.HSICalibrationValue = RCC_HSICALIBRATION_DEFAULT;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_NONE;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_HSI;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV1;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_0) != HAL_OK)

{

Error_Handler();

}

PeriphClkInit.PeriphClockSelection = RCC_PERIPHCLK_ADC;

PeriphClkInit.AdcClockSelection = RCC_ADCPCLK2_DIV2;

if (HAL_RCCEx_PeriphCLKConfig(&PeriphClkInit) != HAL_OK)

{

Error_Handler();

}

}

static void MX_ADC1_Init(void)

{

ADC_ChannelConfTypeDef sConfig = {0};

hadc1.Instance = ADC1;

hadc1.Init.ScanConvMode = ADC_SCAN_DISABLE;

hadc1.Init.ContinuousConvMode = DISABLE;

hadc1.Init.DiscontinuousConvMode = DISABLE;

hadc1.Init.ExternalTrigConv = ADC_SOFTWARE_START;

hadc1.Init.DataAlign = ADC_DATAALIGN_RIGHT;

hadc1.Init.NbrOfConversion = 1;

if (HAL_ADC_Init(&hadc1) != HAL_OK)

{

Error_Handler();

}

sConfig.Channel = ADC_CHANNEL_0;

sConfig.Rank = ADC_REGULAR_RANK_1;

sConfig.SamplingTime = ADC_SAMPLETIME_1CYCLE_5;

if (HAL_ADC_ConfigChannel(&hadc1, &sConfig) != HAL_OK)

{

Error_Handler();

}

}

static void MX_TIM1_Init(void)

{

TIM_MasterConfigTypeDef sMasterConfig = {0};

TIM_OC_InitTypeDef sConfigOC = {0};

TIM_BreakDeadTimeConfigTypeDef sBreakDeadTimeConfig = {0};

htim1.Instance = TIM1;

htim1.Init.Prescaler = 0;

htim1.Init.CounterMode = TIM_COUNTERMODE_UP;

htim1.Init.Period = 65535;

htim1.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim1.Init.RepetitionCounter = 0;

htim1.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_DISABLE;

if (HAL_TIM_PWM_Init(&htim1) != HAL_OK)

{

Error_Handler();

}

sMasterConfig.MasterOutputTrigger = TIM_TRGO_RESET;

sMasterConfig.MasterSlaveMode = TIM_MASTERSLAVEMODE_DISABLE;

if (HAL_TIMEx_MasterConfigSynchronization(&htim1, &sMasterConfig) != HAL_OK)

{

Error_Handler();

}

sConfigOC.OCMode = TIM_OCMODE_PWM1;

sConfigOC.Pulse = 0;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCNPolarity = TIM_OCNPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

sConfigOC.OCIdleState = TIM_OCIDLESTATE_RESET;

sConfigOC.OCNIdleState = TIM_OCNIDLESTATE_RESET;

if (HAL_TIM_PWM_ConfigChannel(&htim1, &sConfigOC, TIM_CHANNEL_1) != HAL_OK)

{

Error_Handler();

}

sBreakDeadTimeConfig.OffStateRunMode = TIM_OSSR_DISABLE;

sBreakDeadTimeConfig.OffStateIDLEMode = TIM_OSSI_DISABLE;

sBreakDeadTimeConfig.LockLevel = TIM_LOCKLEVEL_OFF;

sBreakDeadTimeConfig.DeadTime = 0;

sBreakDeadTimeConfig.BreakState = TIM_BREAK_DISABLE;

sBreakDeadTimeConfig.BreakPolarity = TIM_BREAKPOLARITY_HIGH;

sBreakDeadTimeConfig.AutomaticOutput = TIM_AUTOMATICOUTPUT_DISABLE;

if (HAL_TIMEx_ConfigBreakDeadTime(&htim1, &sBreakDeadTimeConfig) != HAL_OK)

{

Error_Handler();

}

HAL_TIM_MspPostInit(&htim1);

}

static void MX_TIM2_Init(void)

{

TIM_MasterConfigTypeDef sMasterConfig = {0};

TIM_OC_InitTypeDef sConfigOC = {0};

htim2.Instance = TIM2;

htim2.Init.Prescaler = 0;

htim2.Init.CounterMode = TIM_COUNTERMODE_UP;

htim2.Init.Period = 65535;

htim2.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim2.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_DISABLE;

if (HAL_TIM_PWM_Init(&htim2) != HAL_OK)

{

Error_Handler();

}

sMasterConfig.MasterOutputTrigger = TIM_TRGO_RESET;

sMasterConfig.MasterSlaveMode = TIM_MASTERSLAVEMODE_DISABLE;

if (HAL_TIMEx_MasterConfigSynchronization(&htim2, &sMasterConfig) != HAL_OK)

{

Error_Handler();

}

sConfigOC.OCMode = TIM_OCMODE_PWM1;

sConfigOC.Pulse = 0;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

if (HAL_TIM_PWM_ConfigChannel(&htim2, &sConfigOC, TIM_CHANNEL_3) != HAL_OK)

{

Error_Handler();

}

HAL_TIM_MspPostInit(&htim2);

}

static void MX_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

__HAL_RCC_GPIOD_CLK_ENABLE();

__HAL_RCC_GPIOA_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

/*Configure GPIO pin : PB0 */

GPIO_InitStruct.Pin = GPIO_PIN_0;

GPIO_InitStruct.Mode = GPIO_MODE_INPUT;

GPIO_InitStruct.Pull = GPIO_PULLUP;

HAL_GPIO_Init(GPIOB, &GPIO_InitStruct);

}

void Error_Handler(void)

{

__disable_irq();

while (1)

{

}

}

#ifdef USE_FULL_ASSERT

void assert_failed(uint8_t *file, uint32_t line)

{

}

#endif /* USE_FULL_ASSERT */

.jpeg)

Tidak ada komentar:

Posting Komentar